Lab Testing and Quality Assurance

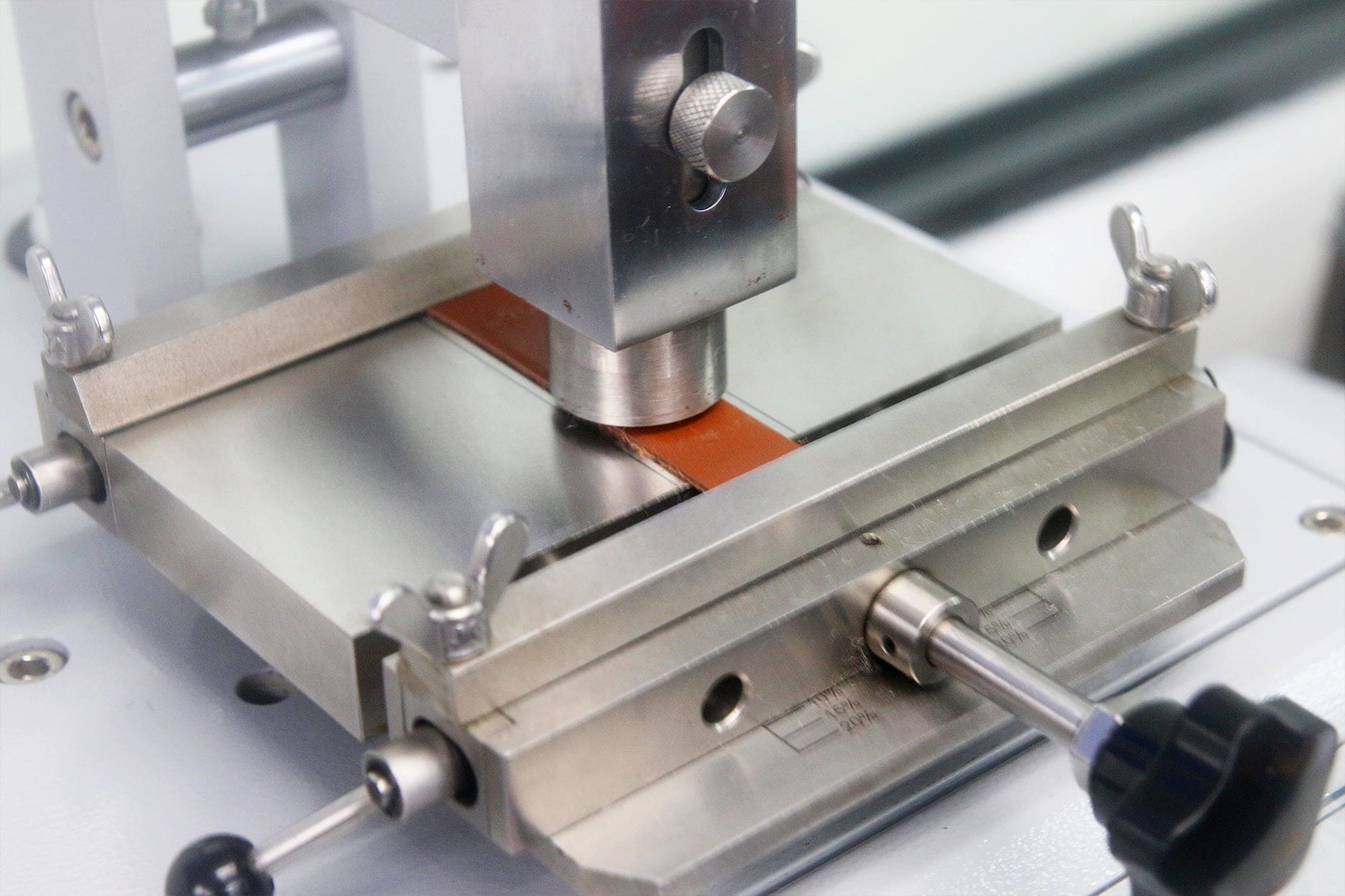

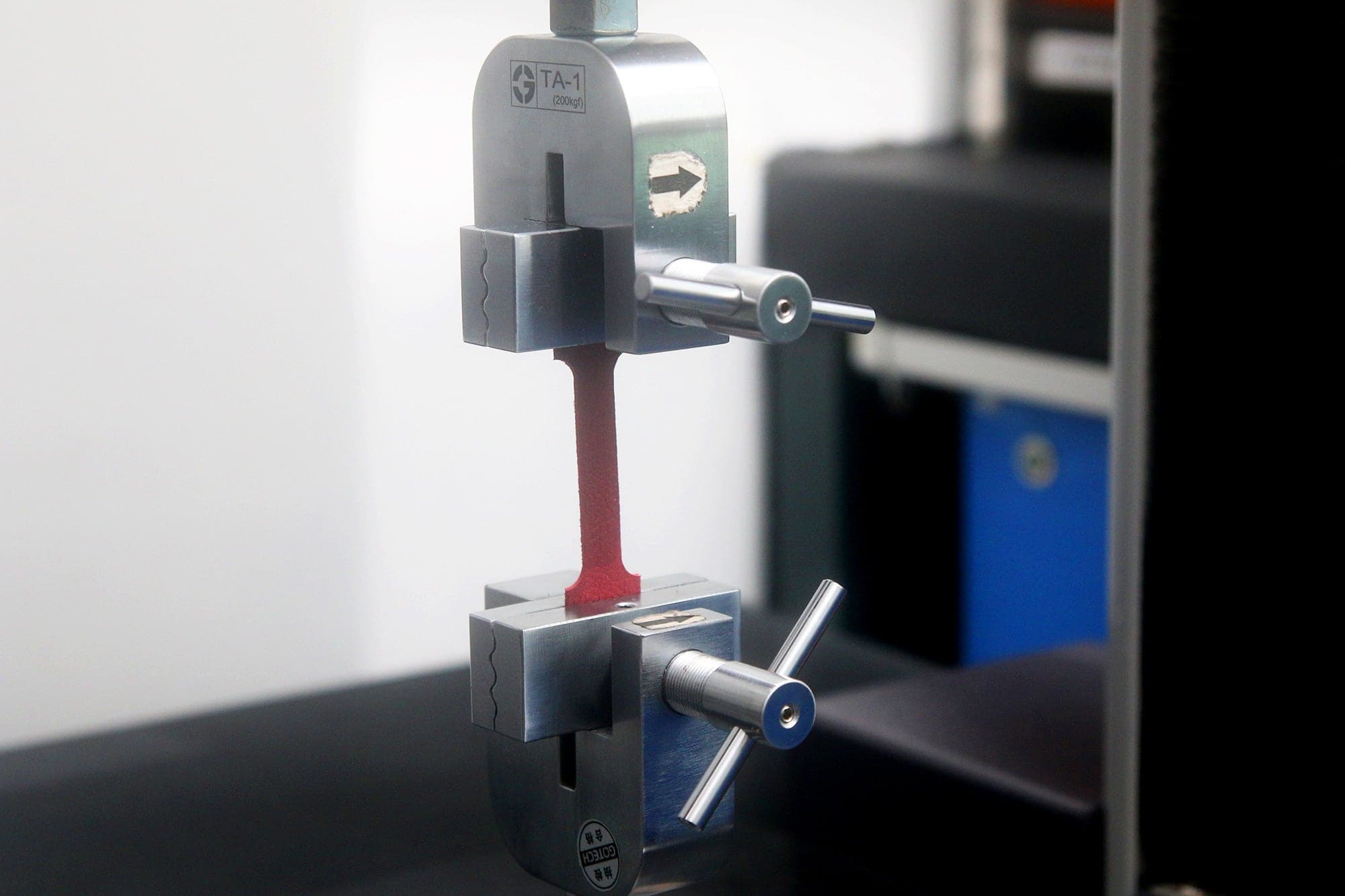

Here at DK SCHWEIZER, we prioritise in providing the best quality of products to our customers. Having our products tested extensively in our laboratory equipped with high grade machinery has proven to produce the best quality leather can offer. Each batch of material that arrives at DK SCHWEIZER ranging from Nappa Leather to PVC, goes through an extensive cycle of tests before being released to our production line. Our test machines consist of universal tester machine, manual press cutter, flexing tester, leather softener tester, rub fastness tester, taber abrasion, gloss checker and spectro.

All of our raw materials are set to meet a certain amount of standards before moving on to other stages of the quality assurance process. These raw materials goes through 25000 cycles of tests in order to meet our standards. Our staff in our laboratory are well trained on managing the machines hence services on the machines are done regularly to fit quality and safety standards.

Our in-house lab will ensure that only the avant-garde leather material is being used to make the car seat upholstery.

NAPPA LEATHER TEST

- Flex Endurance Test

- Colour Fastness to Rubbing

- Abrasion Resistance Test

LEATHER TEST

- Flex Endurance Test

- Colour Fastness to Rubbing

- Abrasion Resistance Test

LEATHER TEST

- Flex Endurance Test

- Colour Fastness to Rubbing

- Abrasion Resistance Test

VINYL

- Flex Endurance Test